V16 Feature Highlights

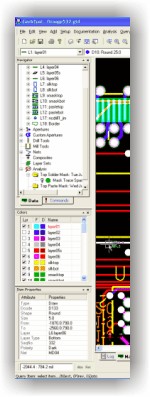

GUI and Navigator

Through the Navigator, you can access vital information about any design: layer information, aperture data, net connectivity, composites, and layer sets. You can set up layer structures by tagging and moving layers into the appropriate order. Blind and buried layer sets can be quickly and easily defined. Apertures can be selected, added, changed, and even dropped into a specific location through drag-and-drop techniques.

You can access all analysis results for processes like Design/Manufacturing Rules Checking, Design For Fabrication, Graphical Netlist Comparison, and even Compare Layers.

Additionally, you have full access to the GerbTool command structure. You can execute individual commands and build a quick “My Commands” list of those commands which are used on a regular basis. Even macros can be accessed and executed here. Again, all of this is performed from a centralized location, virtually eliminating the need for menus and toolbars.

Enhanced! Support for More than Just Gerber

You will be pleased to find that GerbTool includes an Import Wizard that goes beyond just importing Gerber data. Using the Import Wizard, you simply direct GerbTool to the location of your data, and it does the rest by detecting the various database formats (Gerber, Drill, Mill, HPGL, DXF, etc.) automatically. If you still use 274D, it will even detect aperture table formats and convert them as well. GerbTool still has format-specific interfaces for all supported database types (Gerber, Barco DPF, DXF, HPGL & HPGL/2, Excellon, Sieb & Meyer, IPC-D-356A, etc.) just in case you are interested in loading a single file or re-loading existing files.

If you have already made the transition away from Gerber data towards a more intelligent method of transfer data from Design to Manufacturing, the you will be happy to find that GerbTool GT-Communicator, GT-Inspector, and GT-Designer come standard with interfaces to formats such as ODB++, ODB++ XML, IPC-2581 (OffSpring). There are optional interfaces also available for DirectCAM (Import Only), and PADS ASCII (Import Only). These formats provide users of GerbTool with the ability to achieve the maximum data transfer of design information to manufacturing for improved quality and reliability during the fabrication of any job flow. Interfacing with other systems has never been easier; take a look at the broad range of support that comes as a result of these formats:

Intrinsic Apertures

GerbTool supports 26 intrinsic aperture types, with full support for ODB++™ intrinsic apertures. Make quick work out of rounded rectangles, square thermals, thermal reliefs, and more.

Graphical Aperture Rule Creator

Let GerbTool eliminate the hassle of reading "one-off" aperture list formats through the use of our new graphical Aperture Rule Creator. Aperture lists are visually displayed, and you can just point-and-click to define columns, shape types, etc. GerbTool automatically builds your rule file, and lets you save it so it can be used again.

Optimizations

Everything you need to optimize a design for manufacturing is just a mouse-click away with GerbTool. Functions such as Draw-to-Flash conversion, Teardropping, converting those nasty special pad shapes (the ones that are always drawn) into flashes, and more. You can even eliminate those 274X composites that your CAD system might be outputting using our Flatten Composite function.

Automatic Drawn Pad Conversion will process an entire data sets “hands-off” while using your Solder Mask layer as a guide to help eliminate errors and increase performance.. Not only will Automatic Drawn Pad Conversion process your data significantly faster than ever before, it will do it with the added benefit of maintaining pads such as rounded rectangles with standard intrinsic apertures – there is no need for custom apertures. In cases were a conversion could not occur and error is logged within the Analysis tree of the Navigator, where the user can review and correct as required.

Solder Mask Generator and OptimizerClick here to see a demo of Solder & Paste Mask Generationwill create a perfect solder mask layer for you, using a comprehensive set of rules that are designed to give you maximum possible clearance while maintaining optimal coverage throughout your design. Special support for fine-pitch pads is provided, with automatic generation of block openings for those areas to prevent web (sliver) problems between pads. Existing solder mask layers can also be optimized to conform to your rule sets using the Solder Mask Optimizer.

Paste Mask Generator and OptimizerClick here to see a demo of Solder & Paste Mask Generationwill be appreciated by any Designer and/or Stencil Manufacturer. Like the Solder Mask Generator, it is driven by a comprehensive set of rules that are designed to give you optimal reduction across a wide variety of pad shapes and sizes. Special support for fine-pitch pads allows for independent X and Y reductions to eliminate paste build-up between pads. If you already have a paste mask layer but are not satisfied with it, let the Paste Mask Optimizer rework it to conform to your rules.

Stencil Enhancements feature was first introduced in GerbTool version 14. In working with some of our existing stencil users we have further optimized the Stencil Enhancement feature to be more flexible in its ability to accommodate a wide range of processing techniques. Originally the Stencil Enhancement feature was designed to work in conjunction with the Paste Mask Generator/Optimizer; however there are times when the need to work from an existing paste mask layer, without any optimization, is needed to enhance those openings necessary so as to comply with your customers requirements. Now you can increase or decrease openings while simultaneously adjusting the shape configuration of a particular pad-pair. In addition, rounded corners can be applied to all enhanced shapes. You will also benefit from the ability to work with either percentages or physical amounts when developing your rules for pad-pair enhancement. You can now “justify” your enhanced openings along any edge of the copper pad that the opening is associated with.

Basic Panelization is simple and straightforward in GerbTool. You have the option of working fully automatic, letting GerbTool calculate copies based upon various spacing rules, or performing a more traditional lay-up based on offset values from the origin. As an added bonus, GerbTool has the ability to quickly step-and-repeat more than one design. All of this will help you to create assembly panel arrays quickly and efficiently.

New! HyperNETLIST Generation

GerbTool provides class-leading performance with HyperNETLIST generation. Even the toughest designs can be processed in a matter of just a few minutes. For example a 12”x12” 16-layer board design with 4mil traces on 4mil spaces can be processed in approximately 10-minutes on a 3Ghz P4 based PC, as compared to 30-45 minutes of our typical competitors. This kind of performance puts GerbTool on par with systems costly tens of thousands of dollars more.

MCM/LTCC Layer Stack-Up means that users can perform a Netlist Generation on their ceramic or foil-based designs. Unlike competitive systems that are limited to just Gerber layers representing insulators, GerbTool allows you to specify Gerber or NC layers as insulators, accommodating a wider array of data input from various CAD systems.

Enhanced! HyperNETLIST Comparison

Using GerbTool's Graphical Netlist Compare you can finally get feedback that makes sense. Some competitive tools only provide you with a generic ASCII text reports; with GerbTool you can see your problems on the screen. Netlist compare finds Shorts, Opens, Nets without Copper, No External Net Points, and Test Pad Size Differences. Each violation is easily accessible through the Navigator.

Pin-Point Error capabilities help speed the process of troubleshooting problems. Mere graphical rendering of the errors isn’t always enough particularly on more complex nets. Users will appreciate GerbTool’s ability to track down the actual location of Shorts and Opens. The faster you can locate your problem the sooner you can resolve it and get your design out for production.

External Net access allows users to graphically see how a set of external net points might compare with an internal net. This information, when combined with Pin-Point Errors, can dramatically aid in your troubleshooting process.

Enhanced! Dynamic DfM Analysis Suite

GerbTool includes a very comprehensive dynamic analysis “suite” which covers Design Information, Design Rules Checking or Manufacturing Rules Checking, Design for Fabrication, Netlist Comparison, and even Embedded Passive Checking. You are provided with 75+ checks to help insure that a given design is "manufacturable." The “dynamic checklist” environment allows for "single-pass" testing of an entire design, even if you want to check for 5 mil spacing on the top and bottom sides, but need 8 mil spacing on the internal layers.

Design Information Analysis provides 25 “quick” board level queries. These queries are used primarily for a broad overview of any given design for quoting purposes. All queries are reported back on a layer-by-layer basis. Some of the more popular checks include Minimum Air Gap, Minimum Trace Width, Hole Counts, Board Size, and Conductive Layer Count. Field Applications Engineers should find these new features particularly useful for the purposes of quoting new jobs and putting together a design summary prior to submitting a job to production.

DRC/MRC Analysis consists of typical checks like Trace-to-Trace, Trace-to-Pad, Pad-to-Pad, Drill-to-Pad, Drill-to-Plane, Minimum Trace Width, Solder Mask Spacing and Annular Ring Clearances for pads and drills, SMD Pitch & Spacing, Silkscreen on Pads, etc.

Embedded Passive AnalysisDFF Analysis offers more manufacturing-oriented checks like Acid Traps, Copper Slivers, Solder Mask Slivers, Solder Mask Bridging, Starved & Isolated Thermals, Pin Hole Detection, Layer Registration, Resist Slivers detection, and more.

Graphical Netlist Comparison rounds out the suite, allowing you to cover all of your checking needs within one environment.

Embedded Passive Analysis (Optional)Click here to see a demo of Embedded Passive Analysis provides verification support to the growing Embedded Passive market. Designers no longer need to agonize over a lack of verification capabilities within their CAD systems when they design with passive resistors. GerbTool will verify such aspects of passive devises as Resistor-to-Terminator Alignment, Minimum Overlap, Termination Pad Width and Extension, and more. You can work with either Additive or Subtractive passive materials. We've even added utilities for verifying your resistor values, and output reports designed to help your fabricator during production. Click here to view the Embedded Passive Analysis brochure.

NC Drill & Mill

Our completely new NC Drill and Mill support will finish off your tooling processes with features such as:

Advanced Tool Table Support provides total control over drill charts; supports plated and unplated tools for increased compatibility with today's CAD systems; mixed tables, supporting both drill and mill tools, can now be generated for increased compatibility with modern NC equipment. Define NC Feeds and Speeds, and Plunge and Extract Rates, to accomodate a wide range of material usage and stack-up requirements.

Multiple Tool Tables support designs with blind & buried vias; plated versus non-plated drill layers with separate tool tables can be accomodated, while still maintaining yet another table for milling; fabricators can now have standardized tool tables that are built around their shop floor tooling, and map a customer's tool information to their standard tables with ease.

NC Compensation Index Tables allow you to control the compensation index for each tool, allowing for support of unique requirements such as finish sanding, and allows the NC operator to make minor adjustments at the machine, rather than sending the job back to CAM for reprocessing.

NC Tool Linking & Maximum Hits increases the life of old equipment that does not have automatic tool break detection or automatic linking. Change tools automatically with no intervention from the operator.

Tool Reordering for Export allows you to change the export order of your tools to accomodate specific shop processes. Easily adapt a customer-provided tool list to your shop-defined tool list.

User-Defined Break Tabs allow you to build custom break tab libraries by saving your definitions and reloading as needed in new jobs. Support for 5 different tab types: simple, stitched, double-stitched, crown, and crown break with stitching. Place tabs on linear segments, arcs, or circles -- with or without compensation.

Interactive Milling allows you to create mill paths using standard "draw" and "edit" commands, even using arcs to provide smooth, flowing mill paths on flex designs or irregular-shaped boards. Move data back and forth between Gerber and NC layers; GerbTool will automatically make the translation.

Drilled Text allows you to drill part numbers, job numbers, etc. into your panels, utilizing the "canned" feature within the Excellon or Sieb & Meyer format to allow for automatic compensation of tool size.

Operator Messages & Stop Commands allow CAM operators to stop machines and/or prompt NC operators with specific messages while a job is in process.

Advanced Panelization (Optional)Click here to see a demo of Advanced Panelization

GerbTool's Advanced Panelization provides a fully self-contained environment that lets you store an unlimited number of panel templates. You can build templates for each of your shop's standard panel sizes, so you'll never have to define another panel configuration again! Multi-job panelization has become more and more popular for optimizing tooling output for prototypes, limited piece count production, and assembly panels. GerbTool supports stepping and repeating multiple jobs within a single panel.

Different Robber (Galvanic) Bars, Venting, and Thieving patterns can be defined for as many layers as necessary through the use of layer sets. Venting and Thieving supports solid, dot, hatch, and starburst patterns on any layer -- GerbTool can accommodate positive and negative polarities with ease.

All of these functions are performed quickly and efficiently, without the hassle of separate editors, special symbols, and complex user interfaces. Coupons, tooling holes, title blocks, and even your one-up designs are just .GTD databases. Combine as many as you like in whatever configuration you like--the possibilities are unlimited!

Hotkey Compatibility Mode

GerbTool's Compatibility Mode emulates the hotkeys from CAM350™ and CAMMaster™, to help new users make the transition to GerbTool more easily.

User Configurable Toolbars

n addition to the improved Navigator, GerbTool takes toolbar usage to the next level by allowing customization of any of the current toolbars found within the product. Most of the menu commands have button equivalents, which you can place anywhere on the screen for easy access. The result is an environment that you can tailor to your specific needs.

Automation and Scripting

Automation is the ultimate goal in almost any environment, be it design or manufacturing, and GerbTool will not let you down. For quick and simple scripting, GerbTool offers traditional macro records and playbacks. But for more advanced environments, like fabrication shops, you will find a full drag-and-drop macro developer environment that enables anyone to produce high quality macros with ease. Our macro developer even comes complete with a built-in debugger at no additional charge.